ES® FACED FIBERGLASS

METAL BUILDING INSULATION (MBI)

ES® FACED FIBERGLASS

METAL BUILDING INSULATION

White Faced Fiberglass Insulation: VR-R Plus & VR-R Supreme

Several Tab Options available

Introducing our Faced Fiberglass Insulation, where innovation meets performance to redefine insulation solutions for metal buildings. Our range includes two standout products: ES® VR-R Plus and ES® VR-R Supreme, each engineered to elevate thermal efficiency and moisture control while meeting the highest industry standards.

ES® VR-R Plus Faced Fiberglass Metal Building Insulation (MBI) is our DIY, MADE IN THE USA cutting-edge solution for enhancing the thermal efficiency and moisture control of metal buildings. Designed to meet the rigorous standards of the NIA Certified Faced Insulation® 404.01-2022, our product combines innovative materials and expert craftsmanship to deliver superior performance in commercial and industrial settings. From its resilient fiberglass blanket core to the high-quality VR-R Plus vapor retarder facing, fiberglass scrim, and metallized polyester film layers, every aspect of our MBI is engineered to optimize energy conservation and indoor comfort.

ES® VR-R Supreme Agro-Foil Faced Fiberglass Metal Building Insulation (MBI), a supreme facing material designed to elevate the performance of fiberglass insulation blankets while serving as a vapor retarder and protective cover. Agro-Foil enhances insulation efficiency with its impressive 95% reflectivity, backed by extensive research from the US Department of Energy and The Florida Solar Energy Center. This innovative solution is engineered with a thick woven fabric substrate, featuring a silver side for optimal reflectivity and a durable white Polyethylene surface, making it ideal for installation under metal roofs. Agro-Foil can be perforated to prevent condensation and applied independently or laminated to fiberglass for added R-Value. Customize your installation with tabs available in various sizes and configurations, ensuring seamless installation and superior sealing. Whether retrofitting existing structures or enhancing new constructions, Agro-Foil stands as the ultimate solution for improving insulation performance and energy efficiency.

ES® VR-R Supreme Agro-Foil Faced Fiberglass MBI is only available in 48″ widths.

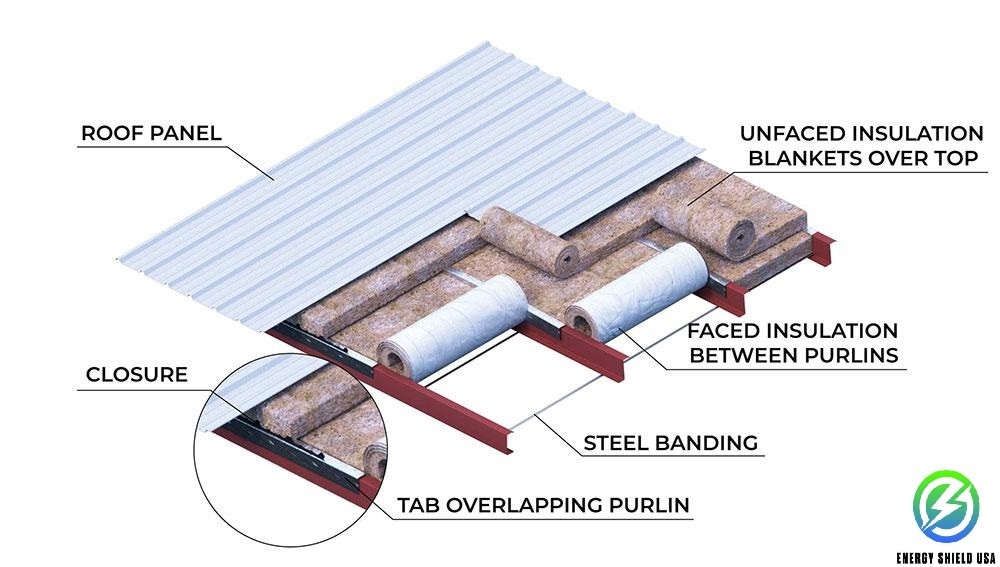

SINGLE LAYER INSULATION SYSTEM

Energy Shield USA provides several different faced fiberglass options

| R-value | Thickness | Widths | Lengths |

|---|---|---|---|

| R-8 | 2.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-10 | 3.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-11 | 3.5″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-13 | 4.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-16 | 5.0″ | 36″, 48″, 72″ | Custom laminated to length |

| R-19 | 6.0″ | 36″ 48″, 60″, 72″ | Custom laminated to length |

| R-25 | 8.0″ | 48″, 60″, 72″ | Custom laminated to length |

| R-30 | 9.5″ | 48″, 60″, 72″ | Custom laminated to length |

*DOUBLE LAYER INSULATION SYSTEM

Apply multiple layers to increase R-values. Purlin depth determines the thickness of bottom layer

| R-Value | Thickness |

|---|---|

| R-29 | 3.0″ + 6.0″ |

| R-30 | 3.5” + 6.0″ |

| R-32 | 4.0” + 6.0” |

| R-33 | 2.0” + 8.0” |

| R-35 | 3.0” + 8.0” |

| R-38 | 6.0” + 6.0” |

| R-40 | 3.0” + 9.5” |

| R-43 | 4.0” + 9.5” |

TAB OPTIONS

Facing tabs are provided for sealing side joints between adjoining rolls of faced fiberglass. Energy Shield USA offers several options:

| Tab Method | Description |

|---|---|

| Double 3″ Staple Tabs | Facing tabs from 2 adjoining rolls are pulled together between fiberglass joint and stapled with a long-nosed staple pliers. |

| Single 6″ No-Staple Tab | First roll of insulation is installed with 6″ tab as leading edge. Next roll is nested over tab from first roll. |

| Single 6″ “Reinforced” No-Staple Tab | Mylar reinforcement is added at 6″ tab to provide rigidity. |

| Single 6″ Self-Adhering No-Staple Tab | An adhesive strip with removable backer is added to 6″ tab for adhering tab to adjoining roll. |

| Double 12″ or 15″ Tabs | For use with double fiberglass layer “High R-Value” systems. Tabs from adjoining purlin spaces are lapped together over purlin. |

| Tuck Tab | For use in single layer application where a single 6″ tab is folded under the facing of the adjacent roll. |