ES® VR-R Plus Faced Fiberglass Insulation (MBI)

USA-made Faced Fiberglass Insulation for metal buildings. ES® VR-R Plus boosts thermal efficiency and moisture control. NIA Certified. Superior performance with fiberglass core, VR-R Plus facing, scrim, metallized polyester layers.

- Boosts Thermal Efficiency

- Moisture Control

- Corrosive Resistant

- Sound Reduction

- Vapor Retarder

- Flame Resistant

- Several Fiberglass Options Available

- Several Tab Options Available

Product Description

ES® VR-R Plus Faced Fiberglass Insulation for metal buildings (MBI) is our DIY, MADE IN THE USA cutting-edge solution for enhancing the thermal efficiency and moisture control of metal buildings. These metal building insulation rolls are designed to meet the rigorous standards of the NIA Certified Faced Insulation® 404.01-2022. Our product combines innovative materials and expert craftsmanship to deliver superior performance in commercial and industrial settings. We engineer every aspect of our MBI, from its resilient fiberglass blanket core to the high-quality VR-R Plus vapor retarder facing, fiberglass scrim, and metallized polyester film layers, to optimize energy conservation and indoor comfort.

SINGLE LAYER INSULATION

Energy Shield USA provides several different faced fiberglass options

| R-Value | Thickness | Widths | Lengths |

|---|---|---|---|

| R-8 | 2.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-10 | 3.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-11 | 3.5″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-13 | 4.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-16 | 5.0″ | 36″, 48″, 72″ | Custom laminated to length |

| R-19 | 6.0″ | 36″, 48″, 60″, 72″ | Custom laminated to length |

| R-25 | 8.0″ | 48″, 60″, 72″ | Custom laminated to length |

| R-30 | 9.5″ | 48″, 60″, 72″ | Custom laminated to length |

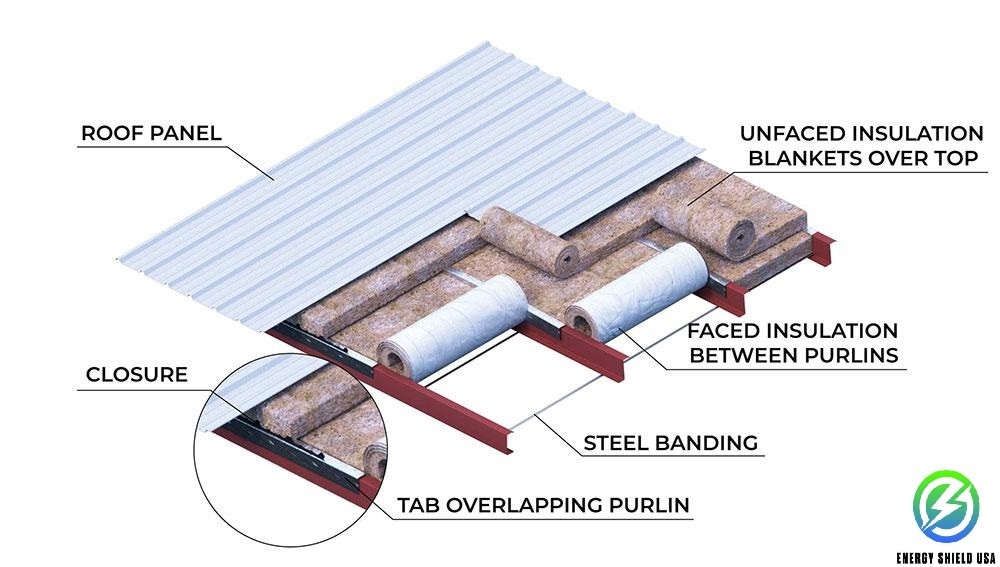

*DOUBLE LAYER INSULATION

Apply multiple layers to increase R-values. Purlin depth determines the thickness of bottom layer

| Double Layers | R-Value |

|---|---|

| 3.0″ + 6.0″ | R-29 |

| 3.5″ + 6.0″ | R-30 |

| 4.0″ + 6.0″ | R-32 |

| 2.0″ + 8.0″ | R-33 |

| 3.0″ + 8.0″ | R-35 |

| 6.0″ + 6.0″ | R-38 |

| 3.0″ + 9.5″ | R-40 |

| 4.0″ + 9.5″ | R-43 |

TAB OPTIONS

Facing tabs are provided for sealing side joints between adjoining rolls of faced fiberglass. Energy Shield USA offers several options:

| Tab Method | Description |

|---|---|

| Double 3″ Staple Tabs | Facing tabs from 2 adjoining rolls are pulled together between fiberglass joint and stapled with a long-nosed staple pliers. |

| Single 6″ No-Staple Tab | First roll of insulation is installed with 6″ tab as leading edge. Next roll is nested over tab from first roll. |

| Single 6″ “Reinforced” No-Staple Tab | Mylar reinforcement is added at 6″ tab to provide rigidity. |

| Single 6″ Self-Adhering No-Staple Tab | An adhesive strip with removable backer is added to 6″ tab for adhering tab to adjoining roll. |

| Double 12″ or 15″ Tabs | For use with double fiberglass layer “High R-Value” systems. Tabs from adjoining purlin spaces are lapped together over purlin. |

| Tuck Tab | For use in single layer application where a single 6″ tab is folded under the facing of the adjacent roll. |

Product Specifications

| PRODUCT DESCRIPTION | |

| WEIGHT | 150 LBS 600 Sq. Ft. |

| WATER VAPOR TRANSMISSION | .02 Perms ASTM E-96-05 |

| TENSILE/TEAR STRENGTH | 35 lbs/inch width (MD) / 35 lbs/inch width (XD) ASTM C1136 |

| ADHESIVE PERFORMANCE | Flame Resistant |

| RESISTANCE TO FUNGI | No Growth ASTM C-1338 |

| ACCELERATED AGING | No Corrosion or Delamination |

| FIRE RATING | |

| FLAME SPREAD | 10 E-84 |

| SMOKE DEVELOPMENT | 35 E-84 |

| NOISE REDUCTION COEFFICIENT | .80 |